Continuous direct compression system consisting of FE CPS, FE55, and operator terminal

Why it pays off - Continuous Manufacturing as a Business Case

The fundamental advantages of Continuous Manufacturing are obvious. However, before making an investment decision, a solid profitability calculation for the entire process should be available. This is exactly what new calculation tools provide—with astonishing results.

Continuous tablet production is becoming increasingly important for pharmaceutical manufacturers facing growing competitive pressure. With the FE CPS, Fette Compacting offers a powerful system that, in combination with a tablet press, forms a continuous direct compression line. However, even if the proof of concept has shown that the manufacture of a product can be successfully transferred to this system, a purchase decision is still a long way off.

After all, when establishing entirely new processes, companies are faced with many more questions, for example, regarding logistics, technical, qualitative, and regulatory requirements, or avoiding investment costs (CAPEX) and operating costs (OPEX), to name just a few. In short, there is no way around a comprehensive profitability analysis.

Identifying potential savings through process comparison

“In practice, it becomes clear that many approaches fall significantly short of comprehensively evaluating the potential of continuous production,” notes Frank Eismann, Senior Consultant Continuous Manufacturing at Fette Compacting. This applies above all to the “cost of goods sold” (COGS), meaning all direct costs incurred by a product ready for sale: raw materials, production, machine running times, energy, personnel, cleaning and setup times, etc.

Fette Compacting has developed special calculation tools to enable companies to base their decisions on a solid foundation. At the heart of these tools is the process comparison tool. This allows companies to estimate initial savings based on their own production data. “This rough orientation – also known as ‘order of magnitude’ – is particularly important in the early project phase, because it often determines whether an investment project is pursued further,” explains Frank Eismann, who played a key role in developing the tool.

Process steps make the difference

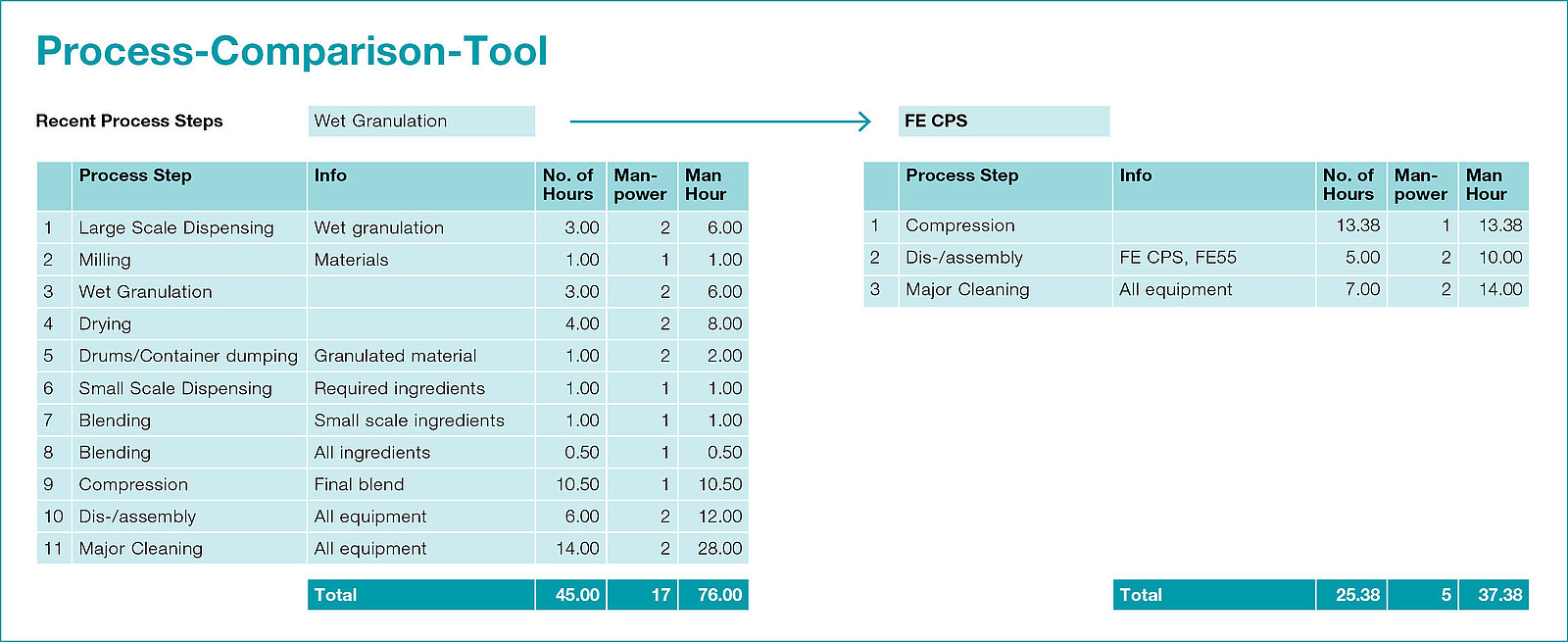

Basically, the system can be used for all products that were previously manufactured using wet granulation, roller compaction, or direct compression. "However, the greatest savings are achieved when companies switch from classic wet granulation followed by tableting to direct compression with the FE CPS plus tablet press. The reason: significantly fewer process steps and plant components," says Frank Eismann. For the specific analysis, the customer provides process data such as processing times and personnel costs for all steps, anonymously if desired. This provides a clear picture of potential savings, which also makes it easier to present arguments to various stakeholders.

Data in the process comparison tool: Even a direct comparison of the number of process steps – 11 versus 3 – illustrates the potential savings

Data in the process comparison tool: Even a direct comparison of the number of process steps – 11 versus 3 – illustrates the potential savings

High savings potential in machine and personnel costs

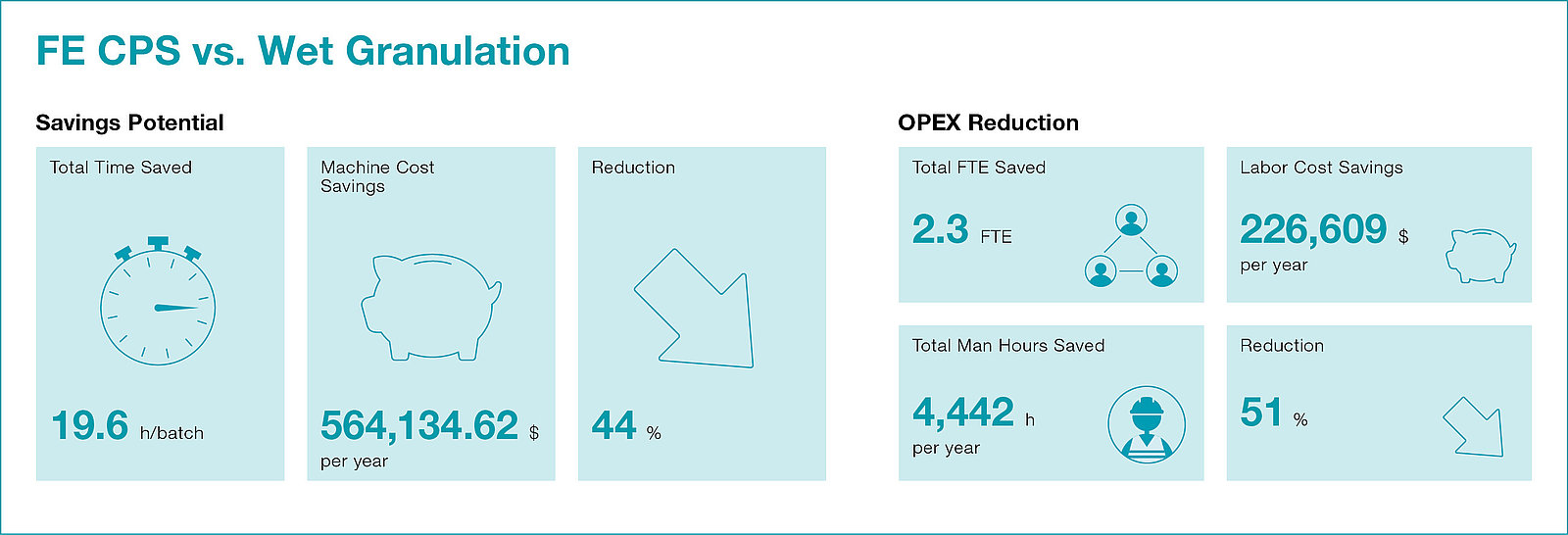

In the case study shown here, a direct compression line based on FE CPS can save more than $560,000 in machine costs per batch over 19 hours and per year compared to wet granulation – around 44 percent. In terms of OPEX costs, this corresponds to approximately 4,440 working hours or 2.3 full-time positions, which can then be allocated to other areas of responsibility.

Savings potential for process comparison of wet granulation and continuous direct compaction

Savings potential for process comparison of wet granulation and continuous direct compaction

Surprise in total output

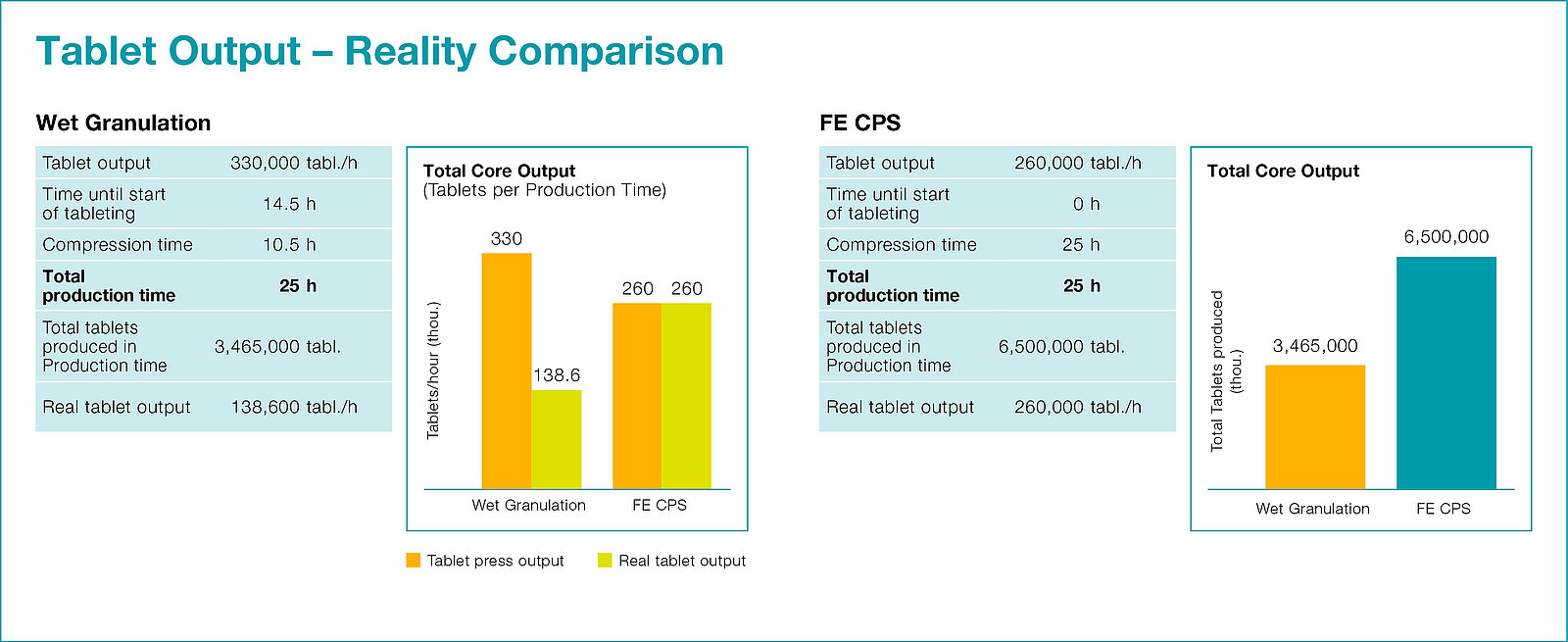

Pharmaceutical manufacturers usually examine the switch to continuous production using a specific product as an example and by asking the question: How does the direct compression line affect the maximum market or order volume? In many production environments, tablet throughput is still used as the benchmark. If the nominal output rate drops - for example, from 330,000 to 260,000 tablets per hour - this is often seen as a loss of capacity.

However, continuous production shows that a direct compression line consisting of FE CPS and a tablet press eliminates numerous lead times, allowing tablets that meet specifications to be produced immediately. This leads to higher overall output despite lower nominal capacity. In this specific example, the actual output is almost twice as high.

Over the entire production period, the output of the direct compression line (right, in turquoise) is significantly higher than when using wet granulation

Over the entire production period, the output of the direct compression line (right, in turquoise) is significantly higher than when using wet granulation

Basis for well-founded decisions

While the process comparison highlights the most important savings potential in the business case, another tool from Fette Compacting takes a close look at energy costs and sustainability indicators. It also supports site master planning—i.e., strategic location planning—in terms of layout, capacity, costs, and sustainability. Here, too, all calculations are based on information provided by customers. A third tool for formulation comparison looks at differences in the selection of raw materials. It shows that raw materials that are more expensive than the ones used previously do not always have to be a deal breaker in the overall calculation. “With these aids, Fette Compacting now offers companies a truly solid basis for investment decisions in Continuous Manufacturing,” summarizes Frank Eismann.